Demand Driven, también conocida como Demand Driven Material Requirements Planning – DDMRP, es una metodología de planificación y gestión de materiales e inventarios. La gran diferencia de esta metodología es que permite a las empresas llevar a cabo un abastecimiento de almacén acorde con la demanda real de su mercado.

Con su uso, las organizaciones pueden acelerar el proceso de toma de decisiones desde la planificación hasta la ejecución del abastecimiento. Enfocándose en la disminución de los grandes cambios en el inventario usualmente llamadas efecto látigo. El demand driven también reduce la dependencia en los pronósticos de venta.

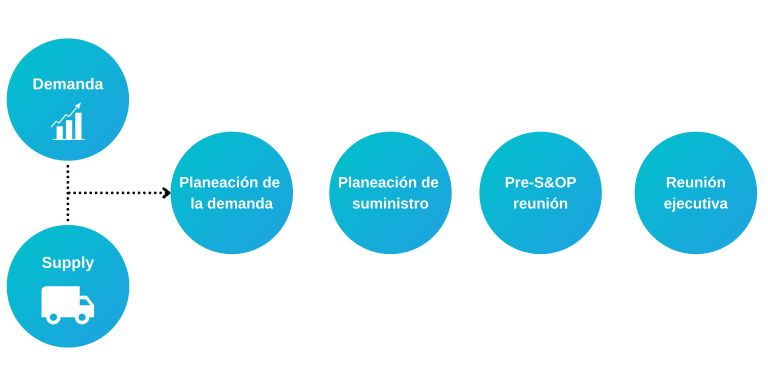

Por otro lado, el concepto de S&OP, en español, la planificación de ventas y operaciones, hace referencia a un método de planificación que busca conciliar el pronóstico comercial con las necesidades o requerimientos de las áreas de logística y finanzas.

El Demand Driven y S&OP buscan mejorar las tareas de la cadena de suministro, con el fin que no ocurran problemas con la disponibilidad de productos. Problemas que puedan provocar un desabastecimiento del stock, fallas en el inventario, poca capacidad productiva y una disminución en la calidad de los servicios.

Demand Driven y S&OP, y la sincronización de la cadena productiva

Ambas metodologías mejoran la integración de todas las áreas de la empresa para conseguir que las empresas puedan tener planes de negocio bien pensados y efectivos a corto y largo plazo.

La implementación del Demand Driven y S&OP ayuda a sincronizar la cadena de suministros con el área de ventas. Sincronización que reduce los costes operativos y aumenta la satisfacción final del cliente.

¿Para qué sirve el Demand Driven?

Con el Demand Driven se puede poner en marcha un sistema de producción conocido como pull de demanda. Eso significa que se activa y dirige de acuerdo con la demanda que registra el sistema de la empresa. Lo contrario a los sistemas push, donde las ventas son presionadas por los niveles productivos o de existencias en el inventario.

Con el Demand Driven se puede poner en marcha un sistema de producción conocido como pull de demanda. Eso significa que se activa y dirige de acuerdo con la demanda que registra el sistema de la empresa. Lo contrario a los sistemas push, donde las ventas son presionadas por los niveles productivos o de existencias en el inventario.

Al poner en práctica una metodología DDMRP la producción se enfoca en las necesidades de los clientes. Además, este método permite a las empresas estar al tanto de las compras actualizadas de sus consumidores, controlar mejor sus inventarios, ser más asertivas con sus decisiones y conseguir mayor rentabilidad y éxito con su oferta.

- Es un sistema que emplea la planeación de los buffers de inventario para absorber lo que se encuentra disponible en el inventario y luego activar la producción.

- Resulta muy efectiva para abastecer la demanda a corto plazo.

- Mejora la percepción que tiene el cliente sobre la empresa, y los niveles de satisfacción por buen servicio aumentan considerablemente.

- Hace perceptible para la empresa a través de números las verdaderas necesidades del cliente.

- El esfuerzo de los colaboradores baja en carga de trabajo y tiempo de dedicación.

- Disminuye la inversión en stock y los gastos relacionados con urgencias.

¿Para qué sirve el S&OP?

La planificación de ventas y operaciones integra diferentes áreas de la gestión de empresas, revisando de manera constante la demanda y los suministros disponibles.

Se comienza por establecer un plan de producción y otras tareas relacionadas con el cumplimiento de ventas. Todo con el objetivo de cumplir con los objetivos empresariales, usualmente relacionados con rentabilidad, productividad y plazos de entrega.

El S&OP determina las tasas de producción siguiendo las indicaciones de la gerencia de mantener, incrementar o disminuir las cantidades de productos en los inventarios o los retrasos. Igualmente, se intenta conservar la mano de obra en niveles estables.

Esta metodología también incluye: planificación de equipos, instalaciones, materiales y finanzas de acuerdo a los objetivos o planes de producción. Por ello, logra tener influencia en áreas como la fabricación, la ingeniería y el marketing.

- Es un proceso importante que equilibra la oferta y la demanda en la cadena de suministro.

- Sincroniza todas las tareas para aumentar la efectividad.

- Integra la planificación operativa con la planificación de finanzas.

- Es una metodología que se trabaja mes a mes siguiendo las pautas de un Plan Operativo Anual. Rinde sus frutos a largo plazo.

- Requiere de colaboración entre los departamentos de la empresa para lograr una correcta integración entre procesos.

Ambas metodologías son excelentes opciones para mejorar los procesos productivos y lograr resultados positivos y rentables de cara al cliente final. Podemos ayudarte a poner en práctica algunos de estos enfoques con soluciones integrales y novedosas de inteligencia artificial.