¿Has escuchado las clasificaciones o rankings en la cadena de suministro?

¿Sabes por qué estas clasificaciones son tan importantes para tu negocio?

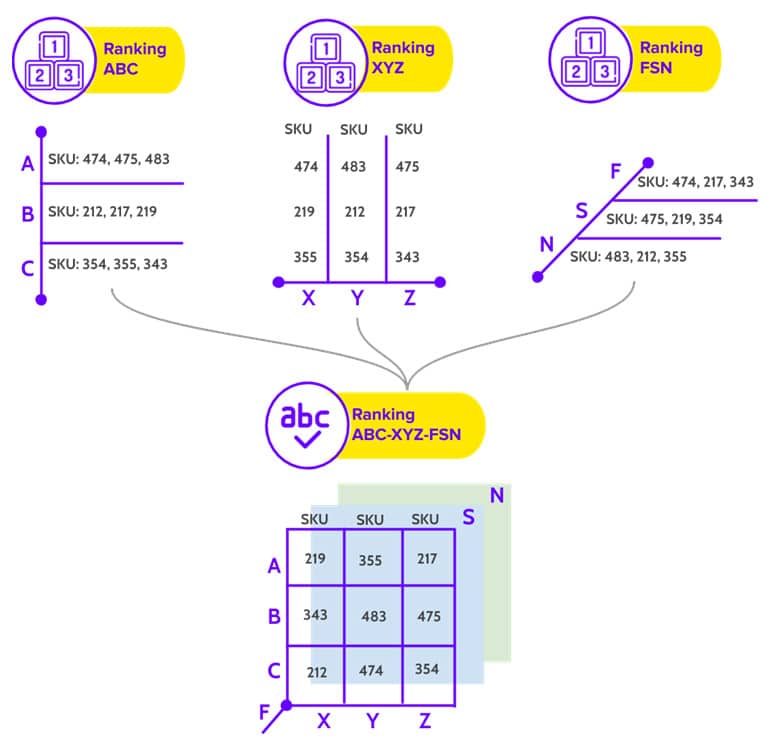

Los rankings o clasificaciones permiten identificar los grupos de SKUs que se comportan de forma similar según diferentes criterios de segmentación.

Los comunes más utilizados por la industria son las clasificaciones realizadas por su participación de ingresos (ABC), variabilidad en la demanda (XYZ) y frecuencia o velocidad de pedidos (FSN).

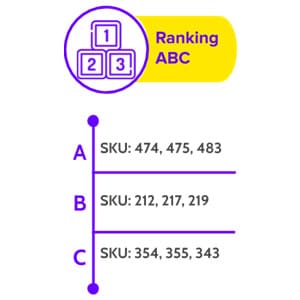

Por convención, el portafolio de SKUs, si se usan estos rankings, se clasifica en 3 grupos dependiendo del criterio de segmentación escogido.

Ranking ABC

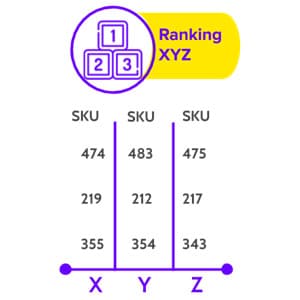

Ranking XYZ

El ranking XYZ a diferencia del ABC, hace la segmentación, clasificación y ordenamiento de los SKUs según el índice de variación que tenga la demanda, costos o ventas.

El objetivo es encontrar cuántos y cuáles son los SKUs con dificultad baja, media o alta, según la variación durante el período de análisis.

A diferencia del ranking ABC, los umbrales de clasificación pueden variar de acuerdo a las características del negocio y los datos, en los cuales se implemente dicho ranking.

Sin embargo, existen unos rangos estándar o iniciales, en los cuales los ítems X o de menor dificultad o comportamiento regular, son aquellos con un índice de variación menor o igual al rango de 25%-33%, los ítems Y o dificultad media cuyo índice de variación es menor o igual al rango entre 66%-75% y los ítems Z o alta dificultad corresponden a cualquier valor que tome el índice de variación superior a los rangos anteriores.

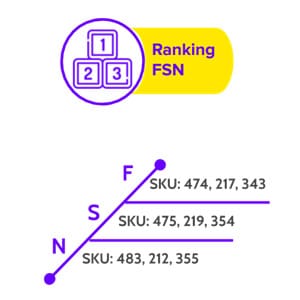

Ranking FSN

El tercer ranking usado comúnmente en la cadena de suministro es el ranking FSN. Este ranking clasifica y ordena los SKUs según su frecuencia o velocidad de movimiento de la demanda, costos o ventas.

El objetivo, es encontrar cuántos y cuáles son los SKUs con movimiento frecuente o rápido, intermitente o lento y estáticos.

Al igual que el ranking XYZ, los umbrales de clasificación pueden variar de acuerdo a las características del negocio y los datos, en los cuales se implemente dicho ranking.

No obstante, se pueden tomar los ítems F o de movimiento rápido con una intermitencia menor o igual al 50%, los ítems S o intermitentes los que manejan una intermitencia entre el 50% y el 75% y finalmente los ítems N o estáticos corresponden a cualquier item que tenga en su intermitencia un valor superior a los rangos anteriormente definidos.

Los rankings presentados anteriormente no son excluyentes entre sí, ni poseen una importancia superior de uno sobre el otro.

Cada uno de ellos es valioso y la necesidad de implementación de uno o de los tres, dependerá exclusivamente de las necesidades, especificaciones y dinámica de tu mercado y tu negocio.

Sin embargo, cuando una empresa decide implementarlos de forma conjunta, logra obtener un panorama completo del comportamiento de los ítems a lo largo del tiempo.

Conocer en detalle la categoría o categorías de cada uno de los ítems de acuerdo a los criterios de clasificación usados, es una información indispensable en nuestra cadena de abastecimiento sin importar el producto o servicio que ofrezcamos, son un indicador viviente que nos permite concentrar nuestros esfuerzos en la generación de los ítems de valor, establecer los cambios en la demanda y optimizar los costos asociados a la estimación de inventarios y nuestra cadena de valor en general, para atender y mantener a nuestros clientes satisfechos sin tener más ni menos inventario del que requerimos para producir y/o distribuir.

Precisamente por la importancia mencionada anteriormente, los rankings ABC, XYZ y FSN no es una clasificación que se debe hacer una sola vez y se escribe sobre piedra, sino que estos deben hacerse de una forma continua, con la finalidad de incluir las tendencias, estacionalidad y outliers que nuestra demanda está presentando.

Estos rankings son el fundamento e insumo indispensable dentro de nuestra cadena de suministro para realizar entre otros los siguientes procesos:

- Establecer prioridades de manejo en nuestra cadena de abastecimiento

- Hacer pronósticos de ventas, demanda y abastecimiento

- Encontrar puntos de reorden

- Mantener el inventario ideal

- Realizar procesos de Slotting & Picking eficientes

- Hacer una distribución más eficiente

- Disminuir costos

- Saber cuales son realmente los activos de mi compañía

- Establecer el capital de trabajo necesario para manejar mi inventario

- Entre otras, recuerden. ¡Los Datos sin innovación son solo Datos!

Aunque los rankings presentados dentro de la cadena de suministro tienen un trasfondo mucho más profundo que simplemente manejar un inventario, somos conscientes que cuando manejamos un volumen alto de ítems, productos, servicios o transacciones, hacer la integración de toda la información de cada uno de ellos, sus costos, demanda, entre otras variables, no es una tarea fácil, sino por el contrario requiere de recursos humanos y tiempo para su elaboración.

En este aspecto, es donde te puedes apalancar en la tecnología y dejar que ella sea la que genere los resultados que requieres, permitiéndote focalizar tu tiempo y el de tu equipo de trabajo en el análisis y generación de políticas y de reglas para tu negocio en cada uno de los grupos de ítems.

La inteligencia artificial es una de las tecnologías que no debes ver ajena en la optimización del proceso de generación de los rankings ABC, XYZ y FSN. Especialmente cuando los volúmenes de ítems que manejas son muy altos.

¿Sabes que cualquiera de los rankings mencionados anteriormente puede ser generado haciendo uso de la inteligencia artificial en segundos en vez de semanas?

Y que este insumo será actualizado teniendo en cuenta tu demanda, su estacionalidad y cambios que se generen en la misma? O que el error en la clasificación será mucho menor?

Bueno, pues estas son solo unas de las tantas ventajas que tienen para brindar, el realizar tus procesos de clasificación a través de los Rankings ABC, XYZ y FSN automatizados a través de inteligencia artificial para ti, tu equipo de trabajo y tu empresa.